Menu

SX2872

Compact and portable|Any position|Transportable case

The SX2872 Flange Facing machine is normally bore mounted, but is equally at home when surface mounted and being used for refurbishing heat exchanger gasket surfaces. The SX2872 machine covers a range of flanges from 711mm (28”) internal diameter to 1829mm (72”) external diameter. The turntable incorporates twin 1.7kW (2.3hp) pneumatic motors, which are designed to compensate for the backlash normally found in spur gear drive systems. The bore mounting base has four sectional legs that ensure precise adjustment while maintaining proper rigidity, even when fully extended. The modular design also makes the SX2872 easy to set up with any of the optional tube sheet and outside diameter mounting kits, which are available on request. Compact, lightweight great for onsite machining

Mounting Base

The mounting assembly enables the machine to be installed in the centre of any flange from 711mm (28”) to 1829mm (72”) in diameter. It consists of a cruciform body provided with four adjustable clamping jaw assemblies. The mounting base is installed and aligned prior to the turntable installation.

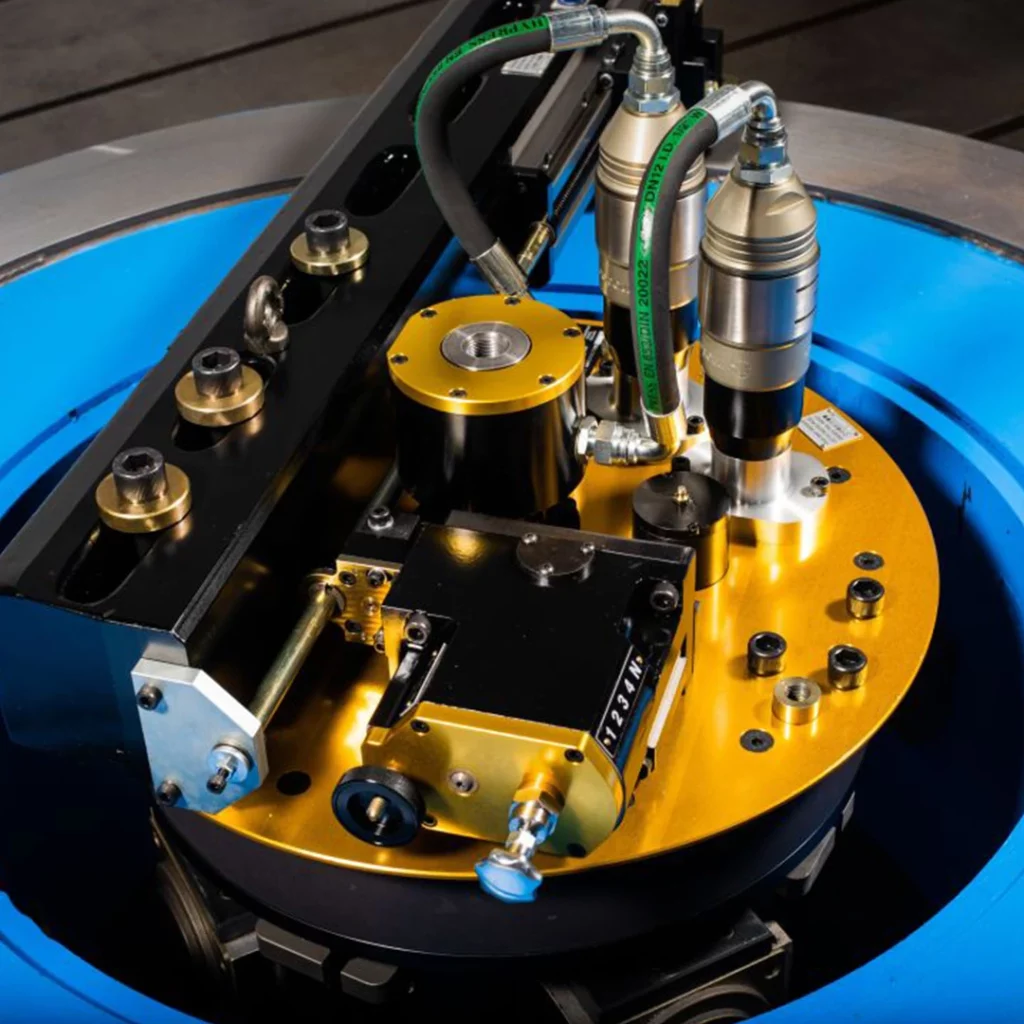

Turntable Assembly

This provides a rigid support for the air motors, gearbox and surfacing assembly. The upper part of the assembly provides the rotational movement for surfacing, whilst the lower part remains stationary, held in position by the mounting base assembly.

Cutting Arm

This is mounted on the turntable assembly and provides a rigid structure to which the toolpost is fixed. Feed in and out is provided by a lead screw, driven by the gearbox output gear. Feed rate is selected at the gearbox. Material, tooling and conditions permitting, the cutting arm assembly can achieve cuts to a maximum depth of 2mm (0.079”) without flange holes and 0.5mm (0.02”) with flange holes

Drive Arrangment

This machine is driven by two pneumatic motor units, mounted directly into the ring gear, which in turn is mounted on the main bearing. The use of two motors enables the overall machine height to be reduced.

Feed Gearbox

The drive gearbox is mounted on the turntable assembly providing a variety of cutting feeds for different applications. Drive input to the gearbox is derived from the mast transfer gear. The gearbox provides four different feed rates selected by a push/pull selector. Traverse is also engaged by a push/pull selector, which gives traverse IN, traverse OUT and neutral. The neutral N position is used for manually positioning the tool post.out the torque and also acts as a backlash eliminator and cushion drive.

Tube Sheet Mounting Kit

Back facing Attachment

Ball Trammel Kit

Application Range

Flange range of 711 mm (28”) to 1829 mm (72”).

Typical Applications

Lens Ring Seat Cutting and Polishing, 'V' Groove Cutting, Tube Sheet Machining

Principle Dimensions

Machine height 534mm (21“) Mounting base thickness 157mm (65/8”) Minimum mounting base diameter 26″ (660mm) Minimum rotational diameter 51″ (1300mm) Toolpost travel standard 16″ (40mm ) Toolpost travel optional 4″ (100mm) Toolpost reach optional 5.11″ ( 130mm )

Weights

Machine weight (less base) 214kg (470lbs) Bass weight (minimum diameter) 87kg (191lbs) Bass weight (minimum diameter) 128kg (282lbs) Nett weight (less wooden case) 486kg (1069lbs) Total shipping weight 552kg (1412lbs) Transportable Wooden Case Dimensions: Length 1400mm (55½”) Height 650mm (255/8”) Width 840mm 331/8”)

General Information

Power Output 30kw (4hp)Gripping range Minimum recommended bore 711mm (28”) - Maximum recommended bore 1727mm (68”) Facing Range: Minimum diameter 259mm (10”) -Maximum recommended diameter 1829mm (72”) Depth of flange required to set the base using standard parts 259mm (10”) Final rotational speed 20rpmDrive Motors (2 off): 2.61kw (3.5hp) Recommended air supply requirements 6 bar 2.69m2/min (90psi 95cfm) Drive motor output speed 275rpm