Decommissioning Services

Mactech Europe can demonstrate over 25 years’ experience in all types of machining in-situ support services.

Mactech Europe has grown to become recognised as a leader in the provision of all types of machining in-situ support services and are uniquely positioned to complete difficult projects in the most demanding environments.

Mactech Europe can demonstrate years of hands-on experience across the decommissioning, offshore, refining, Industrial maintenance, petrochemical, power generation, shipbuilding, and installation market sectors.

With a wide selection of Subsea and Topside cutting equipment available along with a technically qualified team Mactech Europe can offer a solution to any challenge.

In addition, Mactech Europe can draw on the technically qualified manpower which is readily available, supported with extensive equipment resources to provide a quality, cost effective range of onsite machining services that achieve desired results within acceptably time frames.

Our range of decommissioning services

Diamond Wire Saw Services

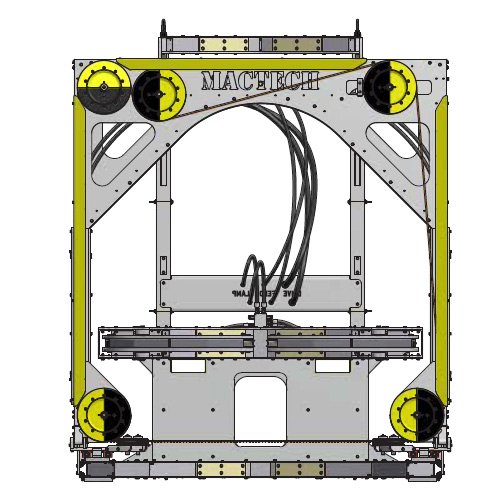

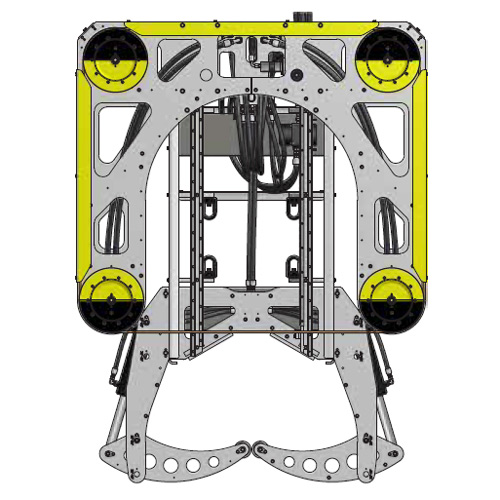

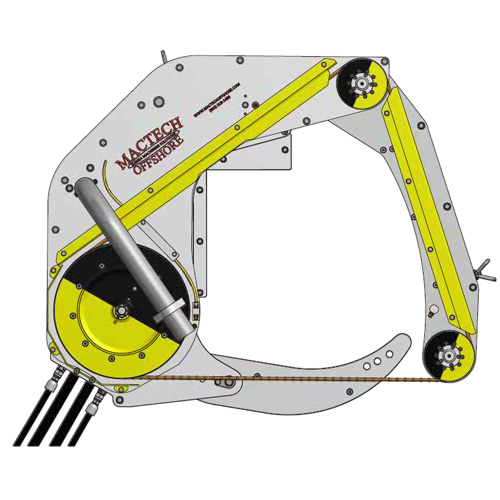

Mactech offers a wide selection of market-leading cutting solutions for use in the harshest of Subsea or topside environments.

Mactech Europe provide cutting services using Diamond Wire Saw Cutters for subsea and topside cutting of a variety of materials and projects. We recommend DWS as ideal for cutting caissons, pipelines, tubulars, subsea jackets, piles, mooring and anchor chains, umbilical’s, flexibles, pipelines, risers, bundles, wells and other structures.

The compact and robust design creates an ideal cutting environment, reducing setup, installation, and removal time – saving you time and money. Find the saw you need knowing Mactech Europe Diamond Wire Saw are easily modified and adaptable to specific project needs.

The versatile range includes an ultra- compact and lightweight 16co DWS, to the large diameter capacity 120i Diamond Wire Saw. The unique 40a articulating diamond wire saw is designed for below the mudline or low clearance cuts. ROV compatibility allows for deep water cutting and maintenance.

All Mactech Europe’s Diamond Wire Saws are designed to give you maximum cutting range flexibility, small footprint and reliable operation

Key Benefits Include:

- Used for cutting caissons, pipelines, tubulars, subsea jackets, piles, mooring and anchor chains, umbilical’s, flexibles, pipelines, risers, bundles, wells and other structures.

- All DWS models can cut in a range of orientations.

- Diamond Wire Saw Cutters to cut from 4.5” to 120”.

- Powerful drive provide fast and accurate cut

- The compact and robust design creates an ideal cutting environment, reducing setup, installation, and removal time – saving you time

- Mactech Diamond Wire Saws are easily modified and adaptable to specific project needs.

- Our versatile range includes the ultracompact and lightweight 16co DWS, to the large diameter capacity 120i DWS

- The unique 40a and 60a Articulating Diamond Wire Saws are designed for below-the mudline cut reducing excavation or low clearance cuts.

- The ROV models are capable of deep water cutting.

Related Equipment

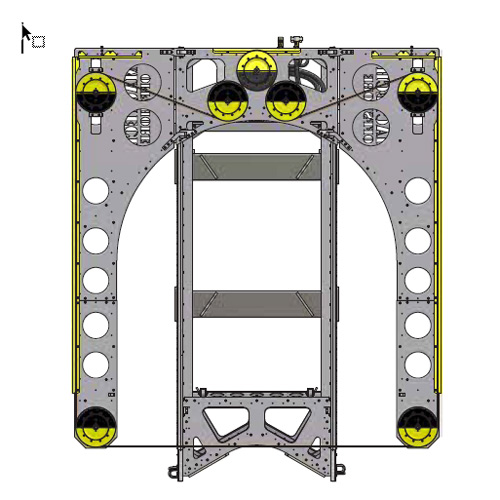

Dual Pin Drill

Mactech Europe provide portable dual pin drilling services using machines that feature opposing drills to cut down on drilling time, saving our customers both time and money.

Mactech Europe has grown to become recognised as a leader in the provision of all types of machining in-situ support services and are uniquely positioned to complete difficult projects in the most demanding environments.

Hinged brackets for fast mounting, up to 36-inch capacity, and sturdy construction make this an ideal tool for use in the harshest environments.

With our in-house design and manufacturing capabilities, we can make purpose built mounting fixtures and modify existing equipment to meet all project requirements.

No matter what your application, Mactech Europe have the equipment and experience to make it happen.

Key Benefits Include:

- Efficient slot recovery drill.

- Versatile mounting configurations

- Opposing drills to cut drilling time

- Large hole diameter

- Hinged bracket mounts for fast setup

- Adjustable to any size casing

- Built of corrosion-resistant material

- Lightest drill in the industry

Related Equipment

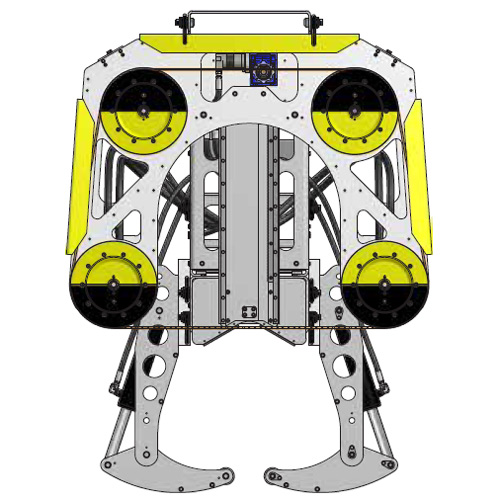

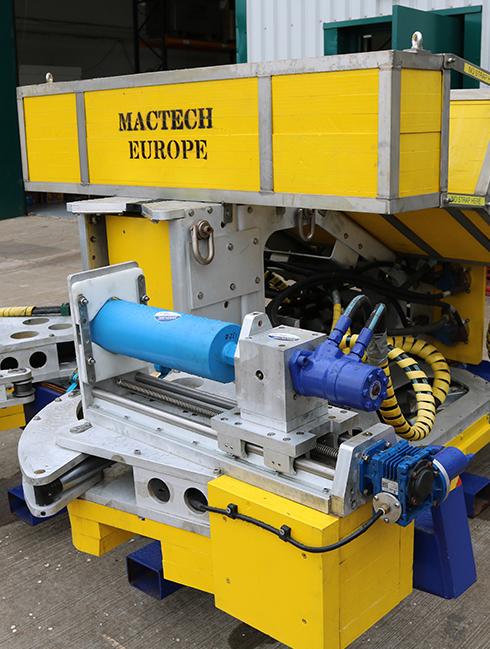

Dual Tool

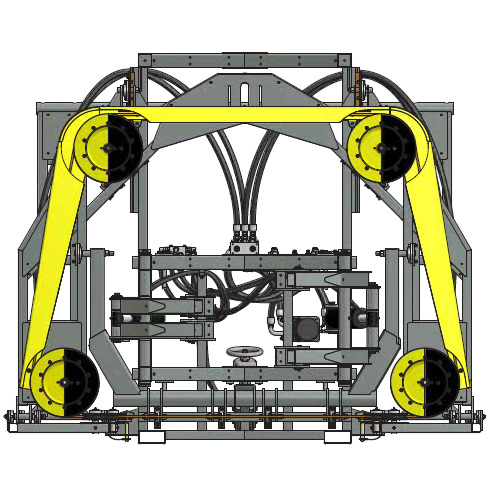

The existing method for topside/subsea core drilling and diamond wire cutting utilises a machine for each operation, diamond wire saw for cutting and dual drilling machine for drilling. Mactech Europe Ltd have developed a combined machine that provides a method of executing drilling and cutting operations in one deployment.

The Mactech dual drilling machine is intended for drilling opposing holes in multi-string casings, pilings, modified for.

The machine is capable of drilling 2 to 6-inch diameter holes in pipes ranging from 14” to 30” diameter. In this application the feed and rotation of the drilling units is controlled remotely with ROV/Diver assistance.

The Mactech diamond wire saw is intended to hydraulically clamp on casings from 14”- 30”. In this application the feed and wire rotation can be controlled remotely from an ROV or manually from topside.

Key Benefits Include:

- Robust dual core drilling system combined with proven diamond wire cutting system

- Reduced operational time

- Reduced equipment and deck space requirements

- ROV user friendly

- The hydraulically driven drill/feed motors can be powered/controlled from topside via HPU/control cart or directly by ROV.

- Diamond wire saw - 2 position (14”-22” & 20”-30”) hydraulic clamping system that securely locks the machine to the target

- Subsea gauges fitted to the saw bulkhead to monitor the cutting and drilling motor pressures

- Diver/ROV operated paddle valves on bulkhead for switching between left and right drill slides

- Hotstab package and 200m rated buoyancy fitted to allow the machine to be free flown/powered by ROV.

Related Equipment

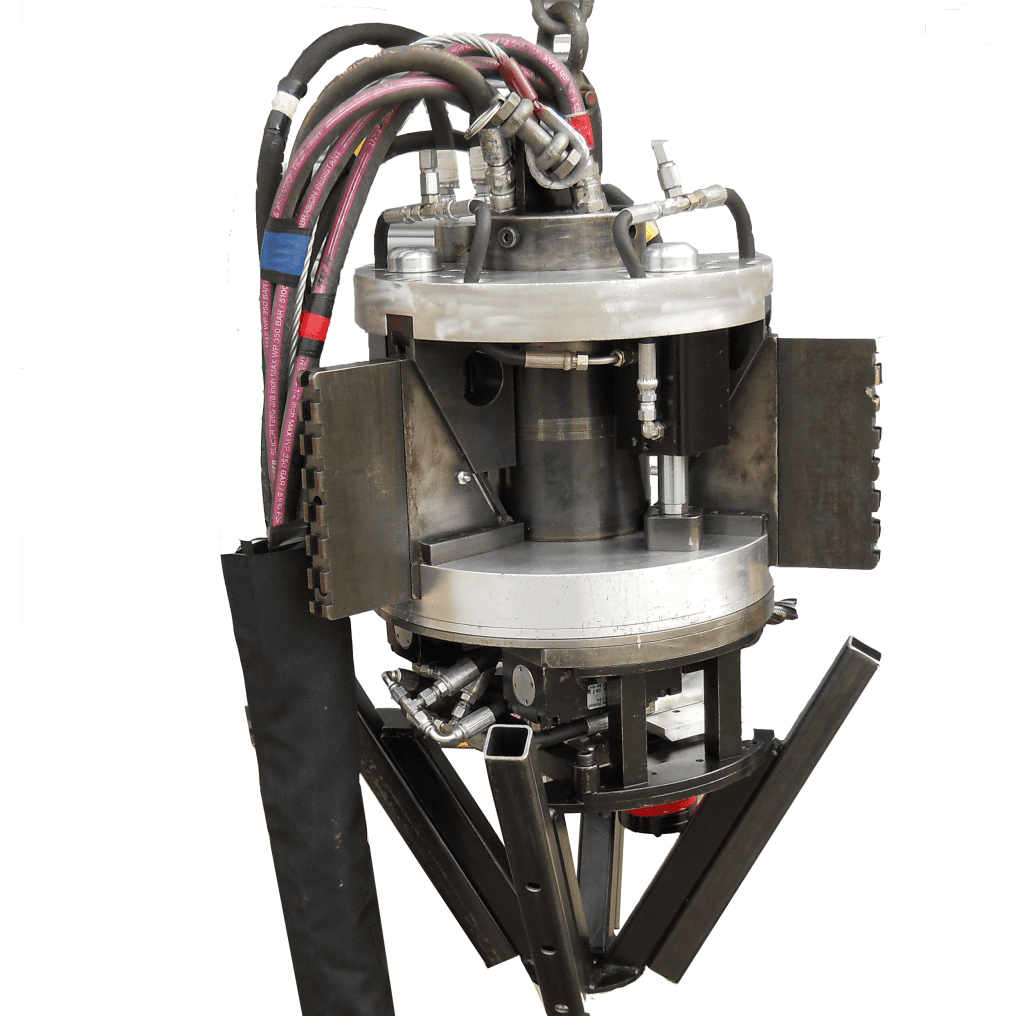

Internal Diameter Pipe Sever

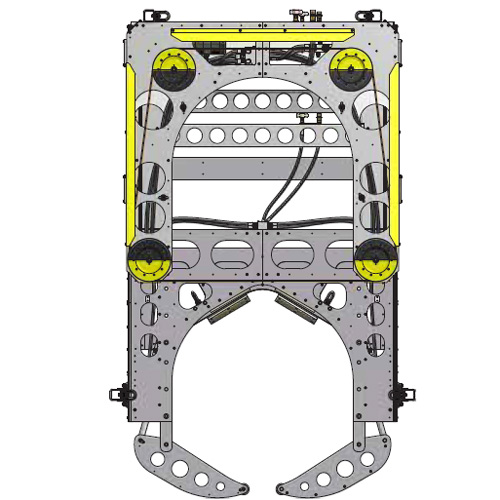

Mactech Europe’s new and innovative internal diameter (I.D) pipe sever machine reliably cuts casing, pilings and other round, hollow tube from the inside diameter.

Key Benefits Include:

- Self-centring makes set-up quick and easy

- Can be configured to a wide range of diameters using locator extensions

- Optional viewing camera for monitoring or visual inspection

- Water jet adaptable

- No external dredging or digging

Related Equipment

Contact Us

- + 44 (0) 1260 281431

- Eaton Bank Trading Estate,

- Riverdane Rd,

- Buglawton,

- Congleton,

- CW12 1PN