In-Situ Machining Services

Mactech Europe can draw on the technically qualified manpower which is readily available, supported with extensive equipment resources.

Mactech has the capability to cut pipes of any diameter and wall thickness thanks to our wide range of OD mounted clamshell pipe cutting machines and our internally mounted end prep machines.

We can machine a broad spectrum of materials such as but not limited to; cast iron, carbon steel, stainless steel & including Super Duplex.

Mactech Pipe Cutting Services have the necessary manpower and equipment resources available to provide a quality, cost-effective service for the benefit of its customers, with the ability to respond at a moment’s notice.

We can provide on-site pipe cutting services globally.

When you require on-site pipe cutting and pipe end preparation services you need a company you can depend on, with quality equipment and knowledgeable technicians.

Our range of In-Situ Machining services

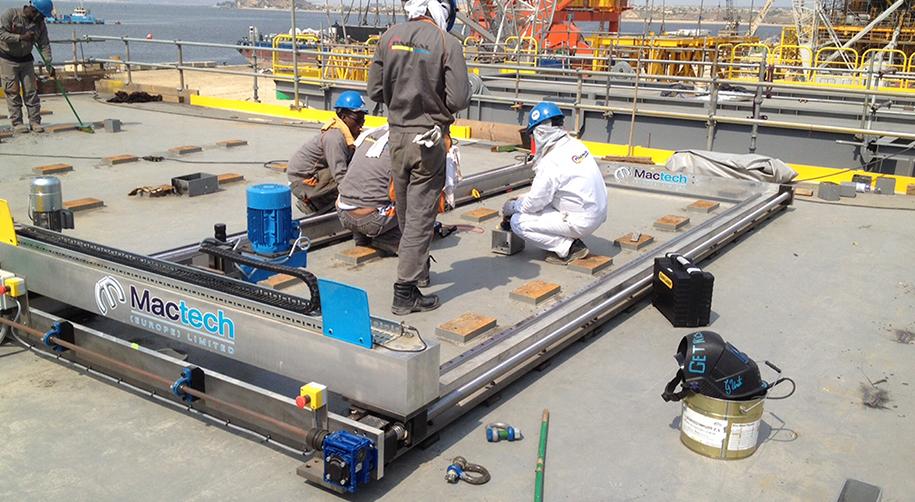

Pipe Cutting

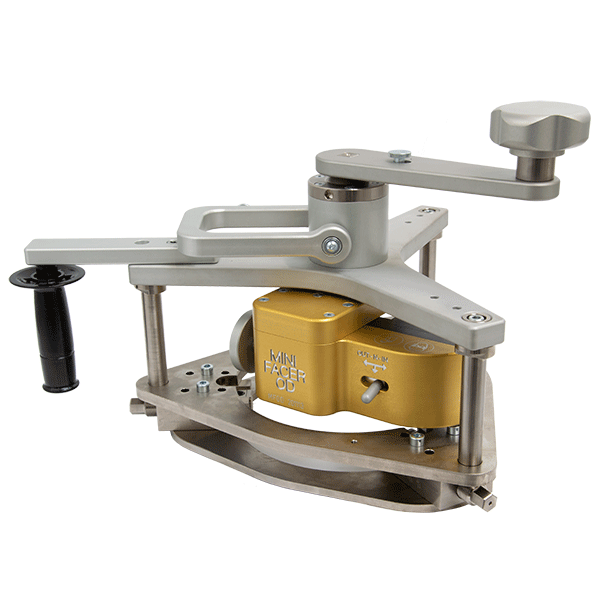

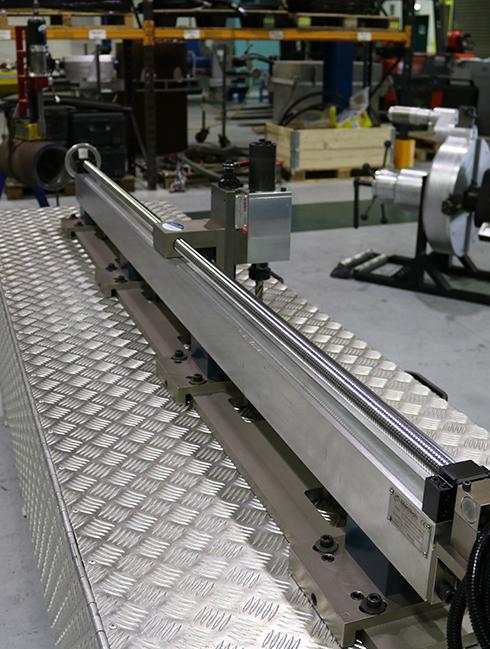

Mactech Europes pipe cutting, and end prepping equipment is amongst the best machines of their kind available today. Clamshell Lathes are supplied to offshore installations, pipe processing yards, shipbuilders, pressure vessel manufacturers and structural and mechanical contractors to name but a few.

Our service technicians are well versed in applications such as weld excavating to remove defective weld material, match boring to enable pipes with dissimilar wall thicknesses to be welded together, generating weld preparations in the standard 30 degree and 37 degree profiles along with compound or ‘J’ bevels and everything else in between.

When you require on-site pipe cutting and pipe end preparation services you need a company you can depend on, with quality equipment and knowledgeable technicians.

Our pipe cutting machines are manufactured and maintained to the highest standards, ensuring that they will perform to the highest tolerances under virtually all conditions.

With its lightweight and rigid construction, it can be used in almost any environment, even subsea.

Key Benefits Include:

- Enables cold cutting in hazardous environments

- Custom set-up and drives for your specific application

- Rigid split frame for precise in-situ machining and repeatability

- Lightweight and designed for handling in tight workspaces

Related Equipment

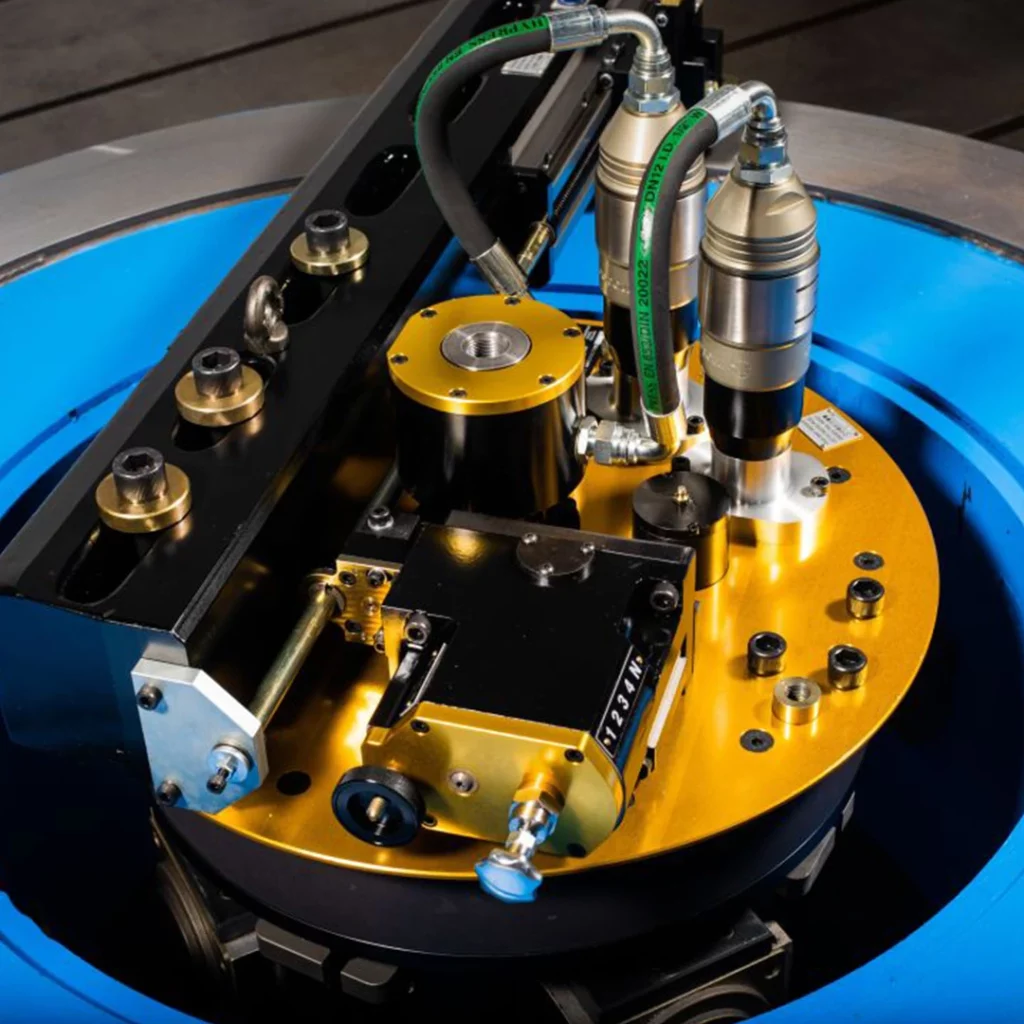

Flange Facing

Mactech Europe can demonstrate over 25 years’ experience in the provision of all types of machining in-situ support services and are uniquely positioned to complete difficult projects in the most demanding environments.

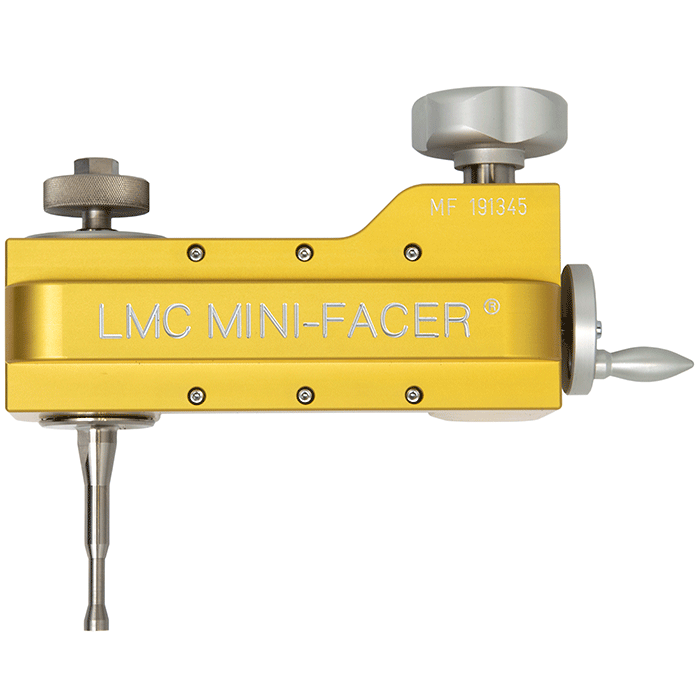

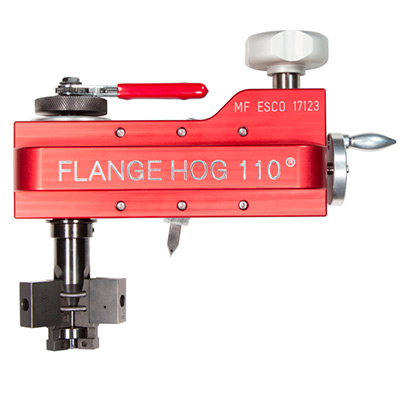

Mactech Europe Ltd has a range of both internally and externally mounted flange facing machines that will cover most applications, when combined with our skilled manpower service you will have the right combination for success.

Our flange facing equipment can maintain high degrees of accuracy, with a variable feed rate to achieve the desired surface finish for all gasket types. All our machines can be pneumatically or hydraulically driven and are highly portable, designed to work in the most demanding of conditions.

Flange Facing is an overall cost-effective technique which ensures the correct surface finish is achieved, aiding the integrity of your piped connections, which in turn helps to keep your plant running efficiently, safely and more environmentally friendly.

Drawing on the technically qualified manpower, which is readily available, supported with extensive equipment resources Mactech Europe can provide a quality, cost effective range of onsite machining services that achieve desired results within acceptably time frames.

Key Benefits Include:

- Compact & lightweight

- Various positions of operation

- Precise and robust

- Pneumatic drive permits use in hazardous areas

Related Equipment

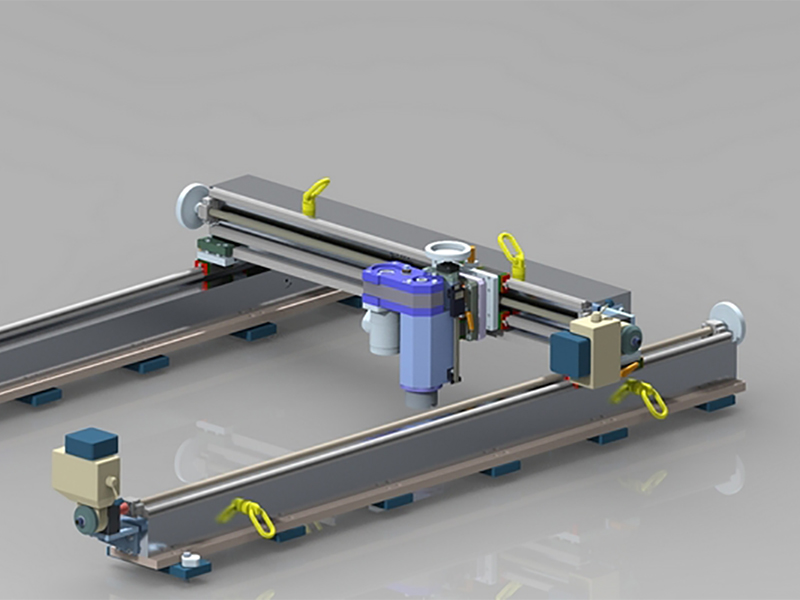

Milling

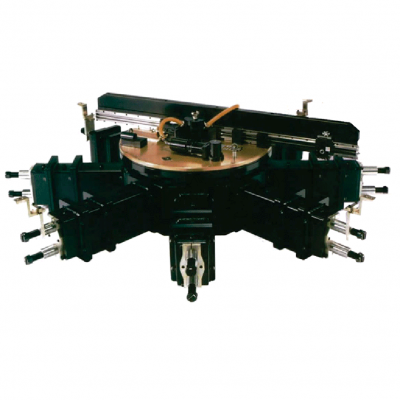

Mactech Europe Ltd can cater for all types of on-site milling requirement. We have a comprehensive range of portable milling equipment, with the capability of milling large areas in a single set up.

Our multi axis portable milling machines have been designed specifically for milling pump and motor bedplates, heat exchanger partition plates & grooves, external and internal keyways, ‘T’ slots, as well as square/rectangular flanges.

With our modular equipment design we can make use of a combination of heads, slides, beams, and rails, configured to provide a diverse range of precision milling services.

Machines are typically fixed to the work piece by utilising existing bolt holes, however, if there are no existing fixing points present, we will drill and tap to suit, or tack weld our equipment into position.

Most on-site milling work falls within our scope of work. The modular construction of our portable milling machines, the power of their pneumatic/hydraulic drives and our capacity to adapt them allows us to cope with most applications.

We are also capable of machining a wide range of materials such as, but not limited to, aluminium, cast iron, carbon steel, stainless steels, and most alloys.

Key Benefits Include:

- Speedy response time Reduced downtime

- Reduced downtime

- High quality finish

- East to achieve flat, level, square faces

- Quick and efficient metal removal rates

Related Equipment

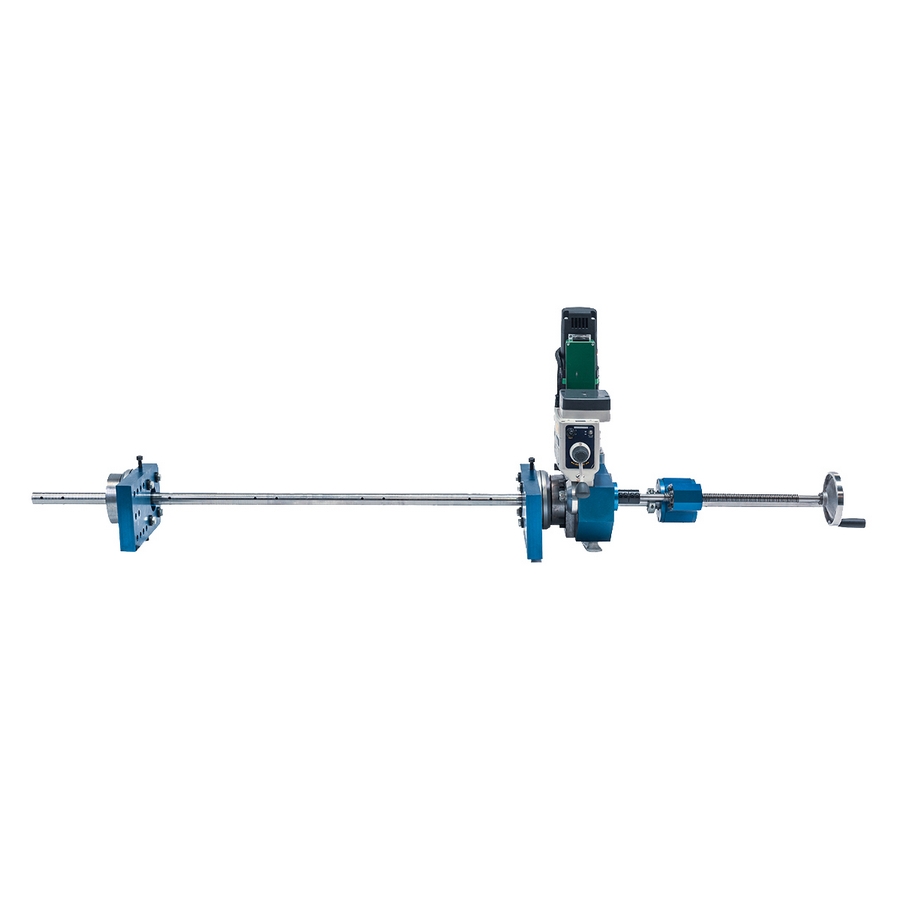

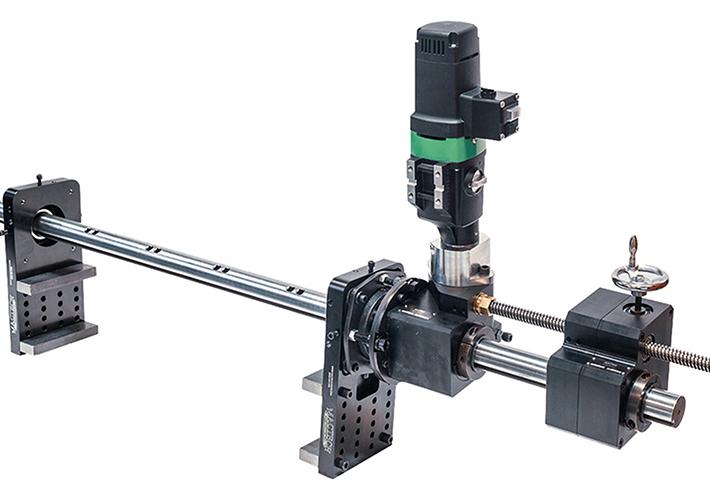

Line Boring

Mactech Europe can demonstrate over 25 years’ experience in the provision of all types of machining in-situ support services and are uniquely positioned to complete difficult projects in the most demanding environments.

Mactech Europe can draw on the technically qualified manpower, which is readily available, supported with extensive equipment resources to provide a quality, cost effective range of onsite machining services that achieve desired results within acceptably time frames.

Mactech Europe’s affordable, on-site machining services will minimise downtime and maximise productivity. Using Mactech’s range of line boring equipment, almost any application can be undertaken, no matter how large or small.

Key Benefits Include:

- Speedy response time Reduced downtime

- Reduced downtime

- High quality finish

- East to achieve flat, level, square faces

- Quick and efficient metal removal rates

Related Equipment

Journal Turning

The Mactech Europe Ltd journal turning solution is a service that is available at short notice when bearing and couplings pick up or drag when being removed or installed on to a shaft, or for shafts that have been damaged or bent by other unexpected occurrences.

Avoid tedious and time-consuming equipment break downs by isolating the area of plant needing to re-machine. Mactech’s pneumatically driven portable machines can repair worn or damaged journals of various diameters quickly and efficiently. Over the years, Mactech have used their journal lathes for many applications within the oil & gas, powergen, marine and OEM markets.

Mactech Europe provide both manpower and journal turning machines for the in situ repair of journals whether the shaft has been built up with weld and requires machining back to the original specification and tolerances or when the shaft needs machining undersize so a repair sleeve can be fitted, Mactech have the right solution to solve your problem.

Our journal turning machines can be positioned in tight areas as it requires the minimum amount of operating clearances. With the simplistic method of set up, the lightweight design and fully adjustable positioning system no job is too difficult to complete.

Typical applications are: –

- Motor gear box shafts

- Turbine shafts

- Hinge pins

- Weld crown removal

Key Benefits Include:

- Speedy response time Reduced downtime

- Reduced downtime

- High quality finish

- East to achieve flat, level, square faces

- Quick and efficient metal removal rates

Contact Us

- + 44 (0) 1260 281431

- Eaton Bank Trading Estate,

- Riverdane Rd,

- Buglawton,

- Congleton,

- CW12 1PN