Menu

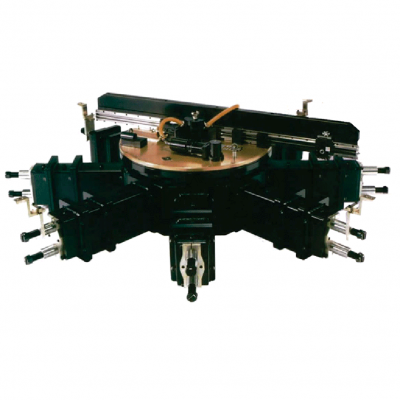

AX48120

Compact and portable|Any position|Transportable case

This is currently the largest internally mounted machine in our range.

It can mount inside flanges having 1219mm (48”) bores and can machine out to over 3048mm (120”) in diameter.

The machine may also be surface mounted, where it is commonly used for crane pedestal and tube sheet refurbishment work.

Like all Silk machines, it is of modular design and operates easily in any orientation.

The standard bore mounting base has eight ram type jaw assemblies, four of which have unique levelling device attachments used to assist with the setting-up operations.

Power is provided by two 3kW (4 hp) pneumatic motors which produce high torque and maximum cutting power.

The same continuous feed gearbox utilized on the AX2872, AX1445 and FXB630 machines minimizes the need for spare parts.

Mounting Base

The Mounting Base is an eight-ram radial clamping chuck. Adjustable clamping jaws on four of the rams are adjusted by an integral rack and pinion arrangement, operating in a similar fashion to a conventional four-jaw chuck. Sectional box lengths bolt together for the appropriate I.D. arrangement.

Turntable Assembly

The Turntable provides a rigid support for the slide arm and incorporates two pneumatic motors and a right angle feed gearbox. It bolts directly to the base after the base model has been levelled and radially positioned. Using the two pneumatic motors enables the torque to be evened out and also acts as a backlash eliminator. Air input to the motor units is via the centre hub manifold.

Cutting Arm

The Cutting Arm, mounted to the turntable, provides a rigid structure to which the toolpost is secured. Feed in and out is provided by a leadscrew, driven by the gearbox pick-up gear. Feed is selected at the gearbox. The cutting arms assembly permits cuts to a maximum depth of 0.079” (0.5mm) with flange holes. A variety of tools can be fitted to the toolpost according to the finish and cut required.

Drive Gearbox

The Drive Gearbox is mounted to the turntable and provides a variety of cutting feeds for different machining applications. Drive input to the gearbox is derived from the hub transfer gear. Four feed rates can be selected by means of a push/pull selector with three positions, traverse IN, traverse OUT and neutral (N).

Feed Gearbox

The drive gearbox is mounted on the turntable assembly providing a variety of cutting feeds for different applications. Drive input to the gearbox is derived from the mast transfer gear. The gearbox provides four different feed rates selected by a push/pull selector. Traverse is also engaged by a push/pull selector, which gives traverse IN, traverse OUT and neutral. The neutral N position is used for manually positioning the tool post.

Tube Sheet Mounting Kit, Tube Sheet Back Facing Kit,O.D. Mounting Kit, Orbital Mounting Kit, Hydraulic Conversion Kit

Application Range

Mount inside flanges having 1219mm (48”) bores and can machine out to over 3048mm (120”) in diameter.

Flange Range

135” (3,429mm) Max O.D., 48” (1,219mm) Min bore, 120” (3,048mm) Max bore

Weights

Weight of turntable (case 1) 2,800lbs (681kg), Weight of base (case 2) 1,361lbs (526kg),Total shipping weight 4,180lbs (1,445kg), Case dimensions (1) 96” x 24” x 51” 2,438 x 610 x 1,295mm, Case dimensions (2) 51” x 13” x 51” 1,295 x 330 x 1,295mm

Power

Power output (2) 3.5hp (2.6kw) motors,