Menu

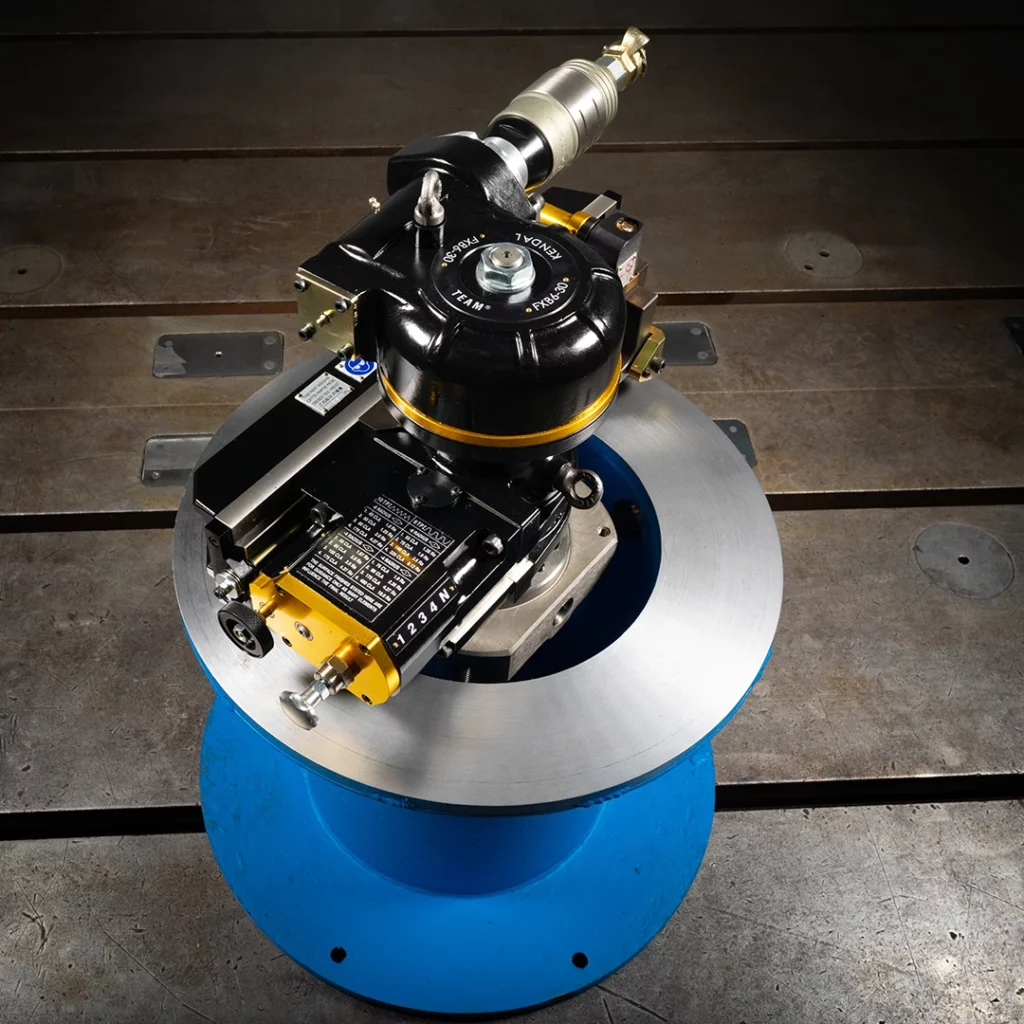

FXB630

Compact and portable|Any position|Transportable case

The FXB630 Flange Facer is modular, compact, and of lightweight construction, designed to resurface flanges ranging from 153 mm (6”) internal diameter to 762 mm (30”) external diameter. It is internally mounted and comes as standard with three clamping modules.

Driven by a 1.7kW (2.3hp) pneumatic motor, this machine is a true workhorse.

Additional versatility is offered by the dovetail slide mounted tool post, which may be swivelled when machining V grooves.

The durable feed gearbox on this machine offers four automatic feed rates to ensure accurate machine settings for a variety of surface finishes.

The versatility of the machine can be expanded via a host of “Bolt-On” extras which are available on request.

Ring

Three separate, hard anodised cast aluminium bases with steel threaded inserts, and adjustable feet enable the machine to be installed perfectly level and central in any flange from 153mm (6″) to 762mm (30″) in diameter. Each assembly consists of a flat triangular casting with a radius across each corner, a hole is tapped into these corners along with one on each flat side which enable the bases to be centralised into a variety of bore sizes. Setting straps are also provided to help in the original positioning of the base to the correct depth.

Drive Hub Assembly

The machine is driven by a 1.2kw (1.5hp) pneumatic motor, mounted directly to the drive hub assembly. This hub provides the drive input to the gearbox and provides a rigid support for the surfacing arm. The whole hub assembly casting is powder coated after machining for a knock resistant finish.

Drive Gearbox

This is mounted directly to the drive hub assembly and with the use of either lead screw provided gives specific surface finishes, (see table opposite). Traverse is selected by a push/ pull rod, which selects traverse IN, traverse OUT and a neutral N position, which is used for manually positioning the tool.

Cutting Arm Assembly

Mounted on the drive hub assembly this provides the rigid structure to which the toolpost is fitted. It can achieve cuts up to a maximum depth of 2mm (0.079″) on flanges without boltholes or 0.5mm (0.02″) with holes and can achieve a flatness better than 0.04mm (0.0015″) at 762mm (30″) diameter. All slideways are coated for rust resistance and 12mm square tooling is supplied as standard.

RTJ Measuring Kit

Ball Trammel Kit

Application Range

Flange range of 6 " (153mm) ID to 30 " (762mm) O.D

Typical Applications

Lens Rng Seat Cutting and Polishing, 'V' Groove Cutting, Tube Sheet Machining

Principle Dimensions

Minimum Diameter 153mm / 6″, Maximum Diameter 762mm / 30″,Machine Height 330mm / 13″,Machine Weight 62kg / 136.7ibs Maximum Rotational Diameter 813mm / 32″,Minimum Rotational Diameter 635mm / 25″,Depth of Flange Required to set the base using standard parts 83mm / 3.1/4″,Machine Height above flange face standard settings 317mm / 12.1/2″,Minimum Recommended Bore 153mm / 6″,Maximum Recommended Bore 711mm / 28″,Tool Post Travel 40mm / 1.5/8″ Recommended Air Supply 1.77m / M,6 bar – 60cfm, 90psi

General Information

Drive motor: 0.66kw (0.85hp), Minimum air supply requirements 5 bar 2.26m3/min (80psi 80cfm), Drive motor output speed 1600rpm, Final rotational speed 33

Weights