A Basic Guide to Understanding Flange Facing.

What is Flange Facing

Flange facing is an essential machining operation that creates new, perfectly flat, and parallel coupling surfaces on the flanges of pipes, valves, and other equipment, ensuring a tight and secure seal when reassembled.

This process is accomplished using a special tool called a flange facing tool, flange facing machine, or flange facer.

The flange facing process is an important action and is used in a wide variety of industries, including oil and gas, petrochemicals, refinery, pharmaceutical production, pipelines, food processing, chemical, and power generation.

It is also used by many other industries during plant and heat exchanger maintenance and shutdown.

How Flange Facing Machines Work

The cutting tool of the flange facing machine travels in a spiral path across the flange face and removes the damaged areas of the face of the flange.

This machining or cutting and polishing operation is completed by successive steps to ensure the face flatness and maintain regularity.

Once the flange facing is finished, the quality of the flange and the proper sealing capability are achieved.

Finishes as per required specifications.

In addition to restoring the integrity of the flange joint, these machines also provide a unique advantage in that they allow for repairs to be made without having to replace the flange, making them a truly cost-effective solution.

Who Conducts Flange Facing

Flange facing does require skilled machinists who use precision instrumentation, which is why the process is often carried out by experienced and certified professionals.

Our machinists at Mactech Europe maintain a high level of expertise and provide a complete range of flange facing services and support, in-situ or in-house at our workshops.

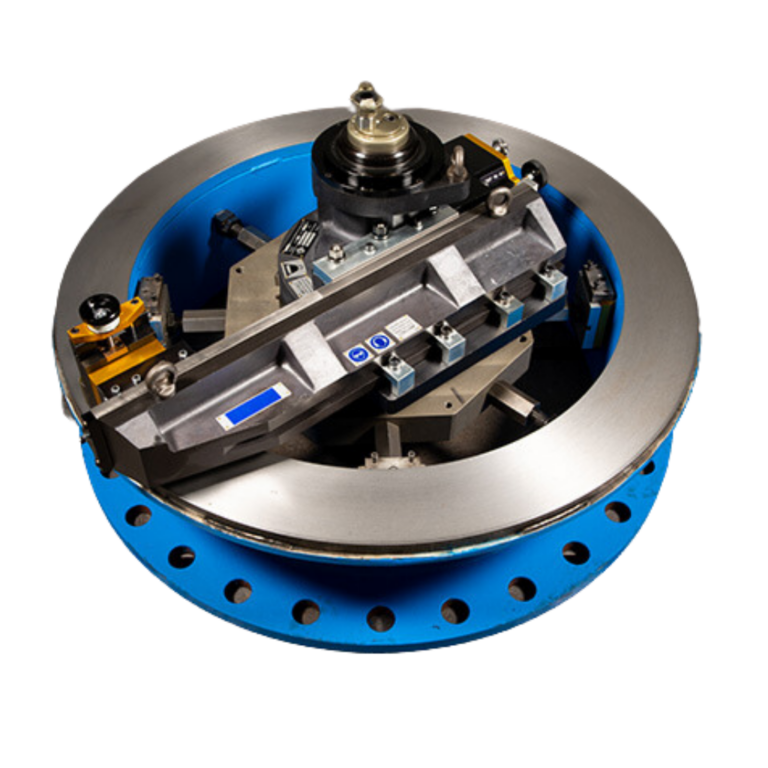

The Silk Flange Facing Machines

Mactech Europe’s Silk flange facing machines are versatile and portable which means that they can be used in a variety of configurations and orientations.

These flange facing machines can be mounted at any angle, including the inverted orientation and are especially useful for situations where the flange must be machined in a difficult-to-reach location.

Mactech Europe’s Flange Facing Machines are invaluable when flanges become deformed due to scratches, dents, or corrosion, as these machines can be used to restore the integrity of the flange.

Silk Flange Facers can be rigidly mounted to the inside diameter or

outside diameter of a pipe for stable and accurate machining.