Menu

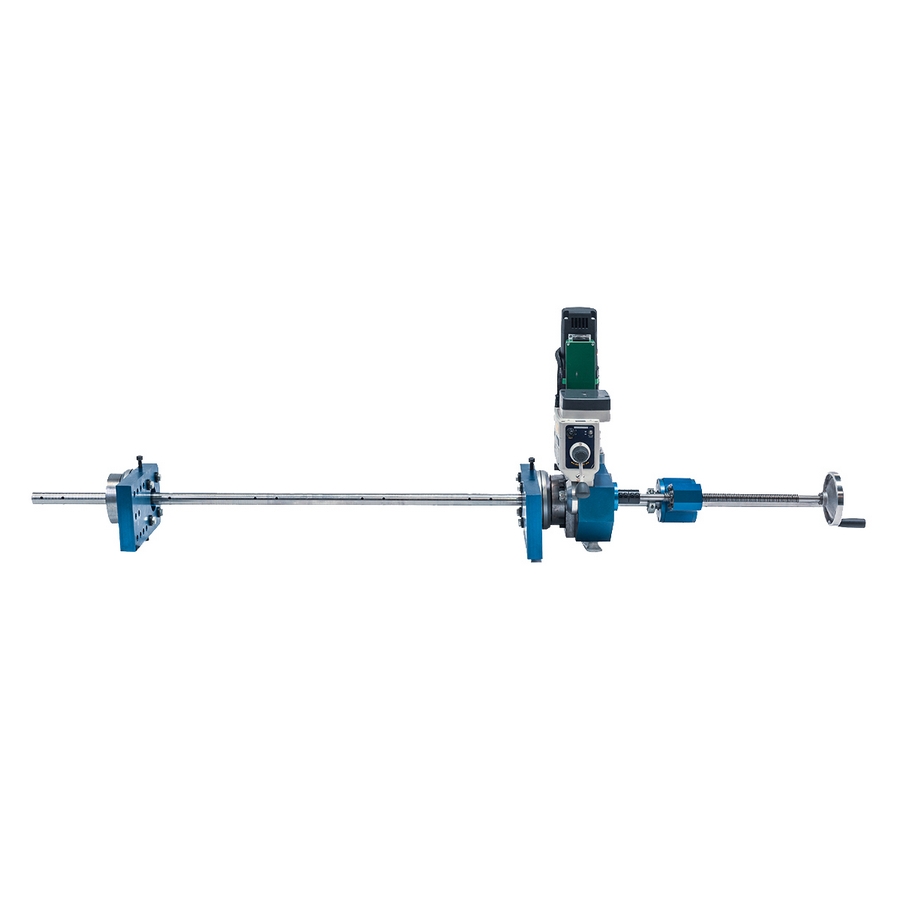

BB1250

Powerful and Versatile|Cuts Through Toughest Materials.|Bi-directional Electrical Variable Feed

Mactech’s portable BB1250 Boring Bar Bore Repair System is a powerful and versatile machine for in-line bore machining, welding and repair.

The compact size and easy set-up make this one of the most efficient bore repair systems on the market.

A powerful variable speed motor can cut through the toughest materials.

The spherical fixture mounting system makes installation and centring easy and accurate.

The 30mm Boring Bar makes your bore repairs quick and easy, all done on- site to save the time and expense of shop repair

Set up

Two alignment cone assemblies for 40-150 mm bores, Self-aligning bearing mounts with spherical bearings

Boring Bar

30mm diameter, stainless steel, two 10mm diameter broaches every 250mm for tool and measuring devices.

BB1250

Powerful and Versatile|Cuts Through Toughest Materials.|Bi-directional Electrical Variable Feed