Menu

MMS

Narrow body|Pneumatic|Electric & battery

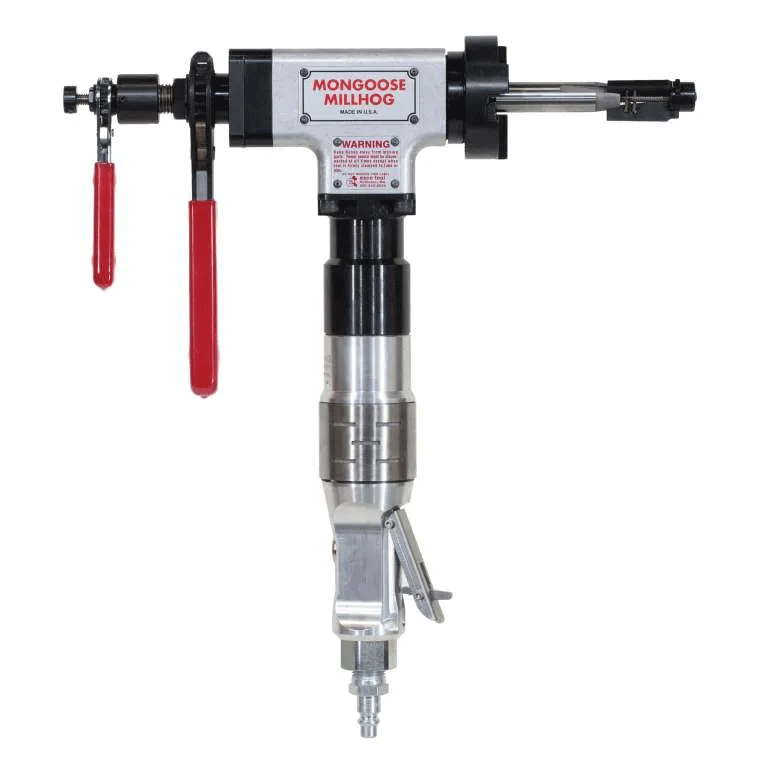

The Mongoose MILLHOG is a torque free beveling machine for tube and pipe from 0.625” (15.9mm) I.D. to 3.0” (76.2 mm) O.D. and is only 2.25” (57.15 mm) wide which makes it ideal for power station boiler tube work and constrained situations with limited access.

Featuring a patented push-pull clamp and release mechanism, it allows the clamps to release from a tube as easily as they tighten. Ideal for beveling, facing and boring on a wide range of tube and pipe alloys, the Mongoose has dual opposed tapered roller bearing and employ the rigid EscoLock blade locking system; which provides chatter-free performance and produces a thick chip without cutting fluids.

Mongoose Mandrel Change from Mactech Europe on Vimeo.

MONGOOSE MILLHOG BASIC KIT #: MG-200, (1) Motor and gear drive assembly (specify motor), (1) Feed mechanism, (1) Mandrel 0.75″ (19.1mm), (1) Draw Rod Assembly, (1) Cutterhead (see cutterhead chart for options), (1) Clamp rib set choice of (G-03A – G-13) (specify), (1) Carrying case, (1) Operating and maintenance Inst., , Note:, Pneumatic motor options add:, (1) 1/2″ hose w/ filter, oiler & 3/8″ coupler, , Battery motor options add:, (2) 5.2ah Li-Ion batteries, (1) Charger

MONGOOSE MILLHOG STANDARD KIT #: MG-300, (1) Motor and gear drive assembly (specify motor), (1) Feed mechanism, (1) Mandrel 0.75″ (19.1mm), (1) Draw Rod Assembly, (1) Cutterhead (see cutterhead chart for options), (11) Clamp rib set (G-03A – G-13), (1) Carrying case, (1) Operating and maintenance Inst., Note:, Pneumatic motor options add:, (1) 1/2″ hose w/ filter, oiler & 3/8″ coupler, Battery motor options add:, (2) 5.2ah Li-Ion batteries, (1) Charger

MONGOOSE MILLHOG DELUXE KIT #: MG-500, (1) Motor and gear drive assembly (specify motor), (1) Feed mechanism, (1) Mandrel 0.75″ (19.1mm), (1) Draw Rod Assembly, (1) Cutterhead (see cutterhead chart for options), (10) Clamp Rib Set (G-03A – G-08) and (H-02 – H-05), (1) MG-400 Wedge Kit, (1) Carrying case, (1) Operating and maintenance Inst., Note:, Pneumatic motor options add:, (1) 1/2″ hose w/ filter, oiler & 3/8″ coupler, Battery motor options add:, (2) 5.2ah Li-Ion batteries, (1) Charger

MANDREL KIT (0.6, 25″ / 15.9MM) PART #: MG-175, The MG-175 mandrel kit is designed for the Mongoose gear head and will allow the tool to fit in tube with 0.625″ (15.9mm) I.D. This kit comes with a specific cutterhead that will fit the smaller 0.625″ (15.86mm) mandrel, along with the draw rod assembly. Clamping range of the Mandrel Kit is 0.625″ (15.9mm) I.D. – .780″ (19.8mm) I.D., Includes, (1) Mandrel 0.625″ (15.9mm), (1) Actuator 0.625″ (15.9mm) and draw rod assembly, (1) Draw rod stop collar, (1) Clamp Rib set G-02A, (1) Cutterhead 2.25″ (57.2mm) for 0.625″ (15.9mm) Mandrel

WEDGE KIT PART #: MG-400, The Mongoose wedge kit is used in applications with heavy wall or when the user needs to extend the range of their Mongoose. Hardware easily slides over the existing ¾” mandrel and comes with a draw rod assembly to fit the bigger H-series ribs. Clamping range of the wedge kit is 1.525″ I.D. – 2.9″ I.D. (38.8mm I.D. – 73.7mm I.D.), Includes, , (1) Wedge, (1) Draw Rod Assembly, (1) Screw, (1) Torque Key, (4) Clamp Rib sets H-02 – H-05

AIR CLAMP PART #: G-270, Air Clamp for the Ground rigidly clamps the tool to the pipe using an air clamp to pull the draw rod instead of the manual clamp wrench. With the flip of a switch, the tool can be clamped or released for high production and reduced cycle times., This accessory is only available with the pneumatic motor., Includes, (1) Air Actuator Clamp System Complete

RIGHT ANGLE DRIVE PART #: G-290, When space is not a luxury, the Groundhog can be fitted with the Right Angle Drive so that the motors can be mounted to either side, or up/down. Kike all of our tools, the Right Angle Drive, is constructed out of precision machined components and is easy to assemble with all three motor options., Includes, Right Angle Drive Complete, (4) Mounting Screws

MEMBRANE REMOVAL PART #: DEPENDENT ON SIZE (SEE SIZE CHART), Cutting head designed to remove the membrane between tubes on a boiler panel., Membrane heads use MRB-8 Inserts, an 8mm carbide bit, to remove material (same insert for Overlay heads)., A specific base cutter head is required for mounting., Includes, (1) Membrane Head (specify size), (3) Mounting Screws, DOES NOT INCLUDE, Base Head, Inserts, Size Chart,Tube Size Membrane Head Base Head # of Inserts1.187″ 30.2mm MO-103 MGB-103 41.25″ 31.8mm MO-104 MGB-104 41.375″ 34.9mm MO-105 MGB-106 41.5″ 38.1mm MO-106 MGB-106 51.625″ 41.3mm MO-107 MGB-106 51.75″ 44.5mm MO-108 MGB-106 52.0″ 50.8mm MO-109 MGB-106 6

OVERLAY REMOVAL PART #: DEPENDENT ON SIZE (SEE SIZE CHART), Cutting head designed to remove the membrane and overlay on a boiler panel that has been coated with overlay material., Uses the same 8mm insert as the membrane heads to remove material., Specific base head is required for mounting. Slightly smaller circumference compared to the membrane heads, forces the head under hard material., Includes, (1) Overlay Head (specify size), (3) Mounting Screws, DOES NOT INCLUDE, Base Head, Inserts, Size Chart, Tube Size Membrane Head Base Head # of Inserts1.187″ 30.2mm MO-203 MGB-103 41.25″ 31.8mm MO-204 MGB-104 41.375″ 34.9mm MO-205 MGB-106 41.5″ 38.1mm MO-206 MGB-106 51.625″ 41.3mm MO-207 MGB-106 51.75″ 44.5mm MO-208 MGB-106 52.0″ 50.8mm MO-209 MGB-106 6

Basic

Basic, MONGOOSE MILLHOG BASIC KIT #: MG-200, (1) Motor and gear drive assembly (specify motor), (1) Feed mechanism, (1) Mandrel 0.75″ (19.1mm), (1) Draw Rod Assembly, (1) Cutterhead (see cutterhead chart for options), (1) Clamp rib set choice of (G-03A – G-13) (specify), (1) Carrying case, (1) Operating and maintenance Inst., , Note:, Pneumatic motor options add:, (1) 1/2″ hose w/ filter, oiler & 3/8″ coupler, Battery motor options add:, (2) 5.2ah Li-Ion batteries, (1) Charger

Standard

Standard, MONGOOSE MILLHOG STANDARD KIT #: MG-300, (1) Motor and gear drive assembly (specify motor), (1) Feed mechanism, (1) Mandrel 0.75″ (19.1mm), (1) Draw Rod Assembly, (1) Cutterhead (see cutterhead chart for options), (11) Clamp rib set (G-03A – G-13), (1) Carrying case, (1) Operating and maintenance Inst., Note:, Pneumatic motor options add:, (1) 1/2″ hose w/ filter, oiler & 3/8″ coupler, , Battery motor options add:, (2) 5.2ah Li-Ion batteries, (1) Charger

Delux

Delux, MONGOOSE MILLHOG DELUXE KIT #: MG-500, (1) Motor and gear drive assembly (specify motor), (1) Feed mechanism, (1) Mandrel 0.75″ (19.1mm), (1) Draw Rod Assembly, (1) Cutterhead (see cutterhead chart for options), (10) Clamp Rib Set (G-03A – G-08) and (H-02 – H-05), (1) MG-400 Wedge Kit, (1) Carrying case, (1) Operating and maintenance Inst., Note:, Pneumatic motor options add:, (1) 1/2″ hose w/ filter, oiler & 3/8″ coupler, Battery motor options add:, (2) 5.2ah Li-Ion batteries, (1) Charger

Rental

Rental, Rental tool kits are setup and packaged to meet your specific job/application., This makes it so your tool is ready to go and only has parts necessary for your job, avoiding confusion and minimizing shipping costs.