Menu

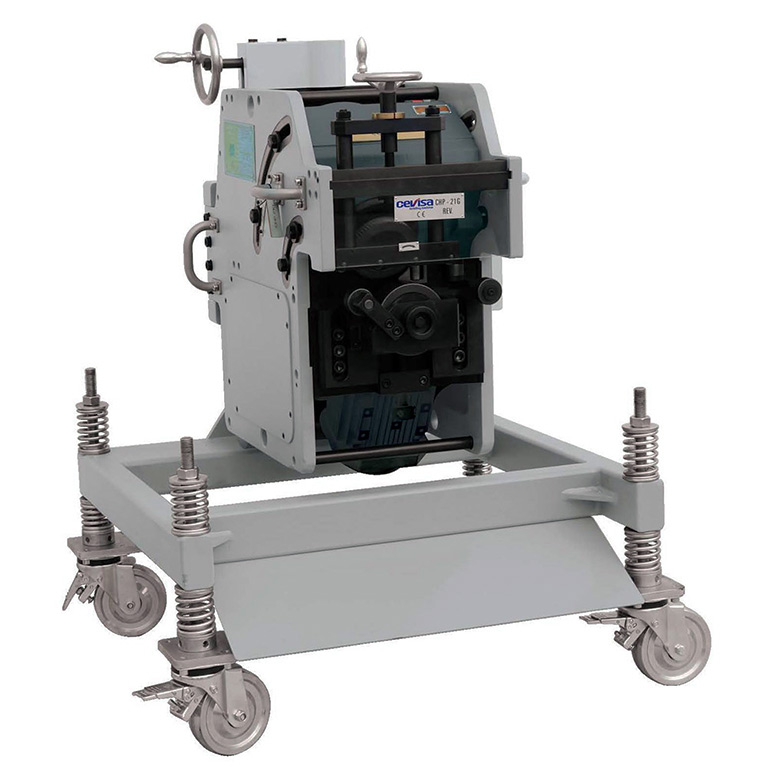

CHP21GREV

Wider optimization|Welding preparation|2 machines in 1

Wider optimization of welding preparation process, the definitive answer for all your bevelling needs, the bevelling machine CHP 21 G REV combines 2 machines in 1, CHP 21 G & CHP 21 G INV.

In less than 1 minute, you can turn it over to bevel in a standard or upside down position depending on your beveling requirements.

Thanks to its design, you can bevel edges in X, Y, K or V in a very short time without any intermediary or dangerous work turning plates.

This high performing and flexible CHP 21 G REV beveling machine will meet all your demands for ergonomic and intensive work. It is easy to use thanks to its simple set-up, self-feed chamfering, quick change position and bevel speed.

Optimum Productive Flexibility guaranteed for wider optimization of welding preparation process and quick return on investment.

3 cutters for mild steel (1 on machine)

1 set of spanners

Cutters for mild steel

Cutters for stainless steel

Cutters for aluminium

Plastic rollers to avoid material marking

Technical Details

Performances, Maximum bevel in one run: 20 mm*, Maximum bevel recommended in several runs: 28 mm*, Maximum recommended thickness: plates and tubes up to 40 mm, Nominal thickness: plates and tubes from 9 mm to 50 mm, Angle variation: from 20° to 45°, Plate beveling: width min. 70 mm, Tube bevelling: Ø min. int.100 mm, Disc bevelling: Ø min. 350 mm, * Dimensions calculated on 400 Mpa steel, bevel length., Bevelling Blueprint, Plate Bevelling in K, V, X and Y, Pipe bevelling: Horizontal position: Bevel in K, V, X and Y Outside or inside is possible (depending on diameter)., Beveling speed: 1.7 meters per minute.

Specifications

Specifications, Motor: three-phase, Motor power: 4 CV – 3 kW, Voltage:, 220/380 V. 50 Hz., 250/440 V. 60 Hz., For other voltages, please consult us, Electric box with:, Emergency stop button, Thermomagnetic switch trip, Switcher, Weight, Net weight: 635 Kg, Works height: adjustable from 850 mm to 880 mm, Built-in trolley